The Dispense Station simulates the process of gluing, bonding, or dispensing an adhesive. This is a multi-step solution that displays our advanced line synchronization capabilities. The station includes two pick-and-place systems, pneumatics components, electronic sensors for parts identification and safety functions, advanced linear motion solutions, and controls. Engineering and programming stations for additive manufacturing are another strength of Morrell Group as an ESV.

How it Works

After the compressed air flows out of the safety manifold, it continues through the rest of the machine. Air splits off at the Dispense Station, where it travels through an AVENTICS HF03 valve manifold with SERCOS III communication. Two valves within the HF03 system control guided cylinders, which stage the container for the gripper and dispense valve.

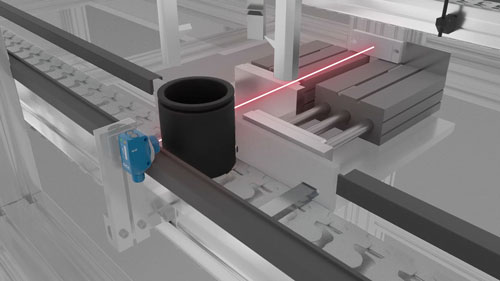

Once a SICK H18 Sensor detects the container, guided cylinders extend to stop the container. This photoelectric sensor provides a continuous indication of signal strength with an illuminated signal strength bar. The SureSense product family can detect nearly any object in any environment, including black, shiny, transparent, and varying colors.

An IndraControl XM22 PLC and IndraDrive Cs servo drives control the CKL module and MS2N motor on the z-axis when the gripper extends to grab the container on this high-speed pick-and-place system. The XM22 PLC has simple, flexible I/O integration and a robust design. The IndaDrive Cs supports Ethernet-based communication, has a multi-encoder interface, and integrated safety technology.

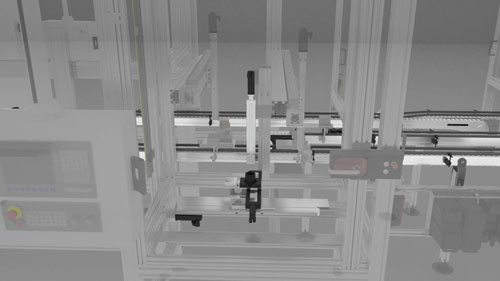

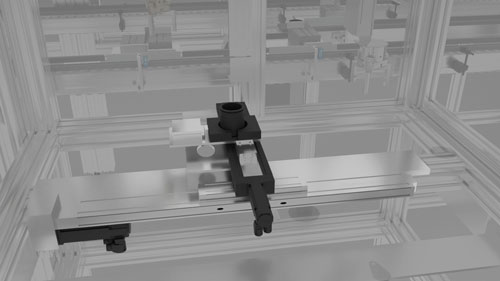

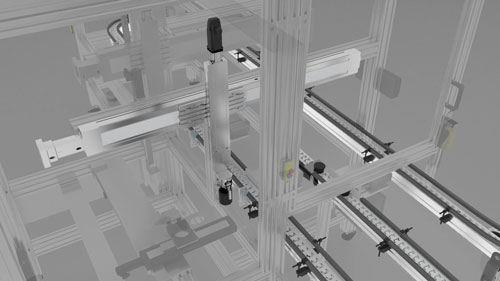

Here, the station simulates the process of engraving, machining, or other additive manufacturing steps. The x-axis is controlled by a CKL-145 linear motor module and the z-axis by a CKK-15-110 ball screw module with an MS2N motor, all from Bosch Rexroth. The CKL and CKK compact modules offer high dynamics and precise positioning in a compact, ready-to-install module. They are available at any desired length and at short notice.

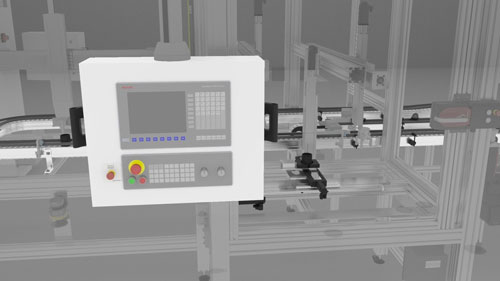

At the dispense simulation, the Bosch Rexroth Micro MTX CNC moves the container from the load station to the dispense station with a basic pick-and-place system. The Micro MTX is a three-axis CNC system with a VDP display unit specifically designed for use with a Micro MTX to move the cup in a circular motion.

A PSK90 Ball Screw Module with an MS2N motor from Bosch Rexroth controls x, y, and z-axis movement. The precision ball screw-driven module is a ready-to-install system with high stiffness and travel accuracy within compact dimensions. The PSK has an integrated Bosch Rexroth Ball Rail System providing optimal travel performance, high load capacities, high precision, and high rigidity. The intelligent and powerful MS2N synchronous servo motor provides more torque, higher speeds, and a single-cable connection.

At the dispense unload station, the 6xz gantry moves the container back onto the conveyor and picks up the lid from the center conveyor. Bosch Rexroth's Micro MTX CNC moves the cup from the dispense station to the unload station. A CKR belt module controls the x-axis, and a CKK ball screw module with an MS2N motor controls the z-axis. Allen Bradley L16ER CompactLOgix PLC programmed in Rockwell Studio 500 controls the dispense station; it utilizes Rexroth's AOI for servo drive control.

An AVENTICS G3 valve manifold provides the appropriate x- and z-axis pressure movement. The G3 electronic Fieldbus platform integrates communication interfaces with I/O capabilities. The valve system is easy to assemble, install, commission, and maintain. Its modern functionality allows logic controllers to turn valves on and off more efficiently and channel I/O data via industrial networks.

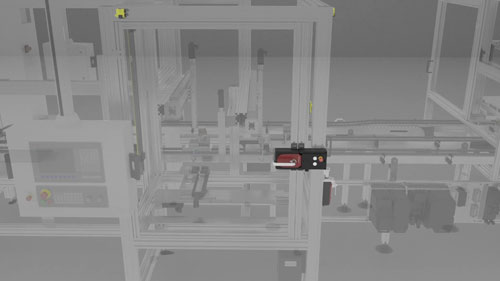

EUCHNER and SICK safety components are used throughout this station to protect the machine user. A EUCHNER Multi-functional Gate Box (MGB) prohibits the machine user from entering the enclosure while the system is running. A EUCHNER gate switch prohibits entry to the station unless the machine user has a specific RFID tag paired to the gate switch. A SICK E-stop button can stop the entire machine when pressed. The safety components are tied to the control panel with SICK's Flexi Loop technology.