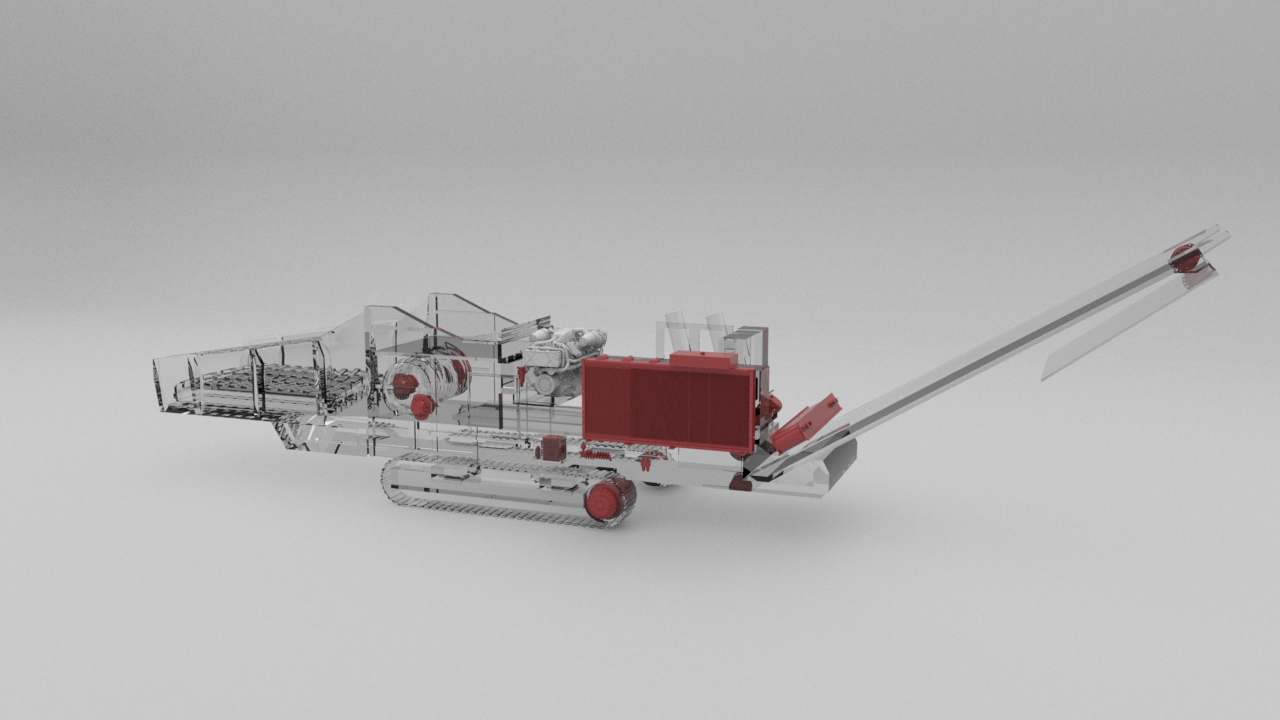

Forestry equipment manufacturers are challenged with building faster, smarter, and safer machines for their customers. The market demands an optimized design; however, manufacturers often experience a shortage of resources to complete the time-consuming research, development, conceptualization, and integration. As an Engineering Partner, Systems Integrator, and Value-Added Distributor (ESV), Morrell Group is perfectly positioned to optimize forestry equipment and streamline the manufacturing process alongside our customers.

Simplified Design System

Morrell Group recently collaborated with a horizontal grinder manufacturer to engineer a simplified system design. Our team provided a revised system design after gathering a full understanding of how the equipment worked and their performance and manufacturing objectives. In the new system design, the number of pumps is reduced. In addition to lowering overall component cost, this also simplified plumbing and provided an optimized footprint. The manufacturer also benefits from reduced installation time thanks to preset pressure settings from the factory.

Morrell Group optimized the control valve layout based on the duty cycle of functions. This optimization process reduced the number of hydraulic hardware components required, thus reducing the overall cost to the manufacturer. The new valve assemblies are delivered to the manufacturer with preset pressure and flow settings, which significantly reduces installation time.

The legacy horizontal grinder system had a mixture of component manufacturers. Morrell Group’s team worked to streamline the manufacturing source to our trusted vendor partners. In addition to providing high-quality components, this also consolidated the training required on the various components and simplified their warranty and service processes.

Early in the process, the Morrell Group team utilized pump and motor sizing resources from our vendor partners to ensure the accuracy of prototype performance. Our team uses actual efficiency data of the pumps and motors to ensure we can meet the performance requirements of the customers’ equipment. This process demonstrates our commitment to accurate prototyping so we get the right product on your machine the first time.

Horizontal Grinder Features and Benefits

In addition to consolidating the pump and valve systems, Morrell Group can engineer a number of new components into the horizontal grinder to provide optimized performance. These solutions can be integrated as is or altered to suit other forestry equipment.

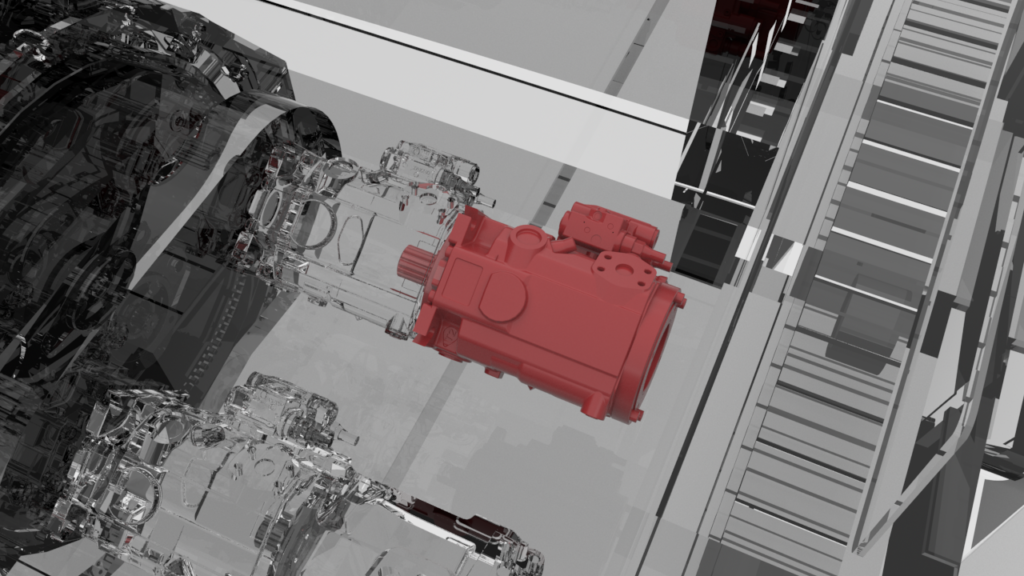

Pump

-

Load sense piston pumps designed for heavy duty forestry applications

-

Reliable load sense valves provide flexibility with their modular design

-

Bankable valve with flow optimized spools

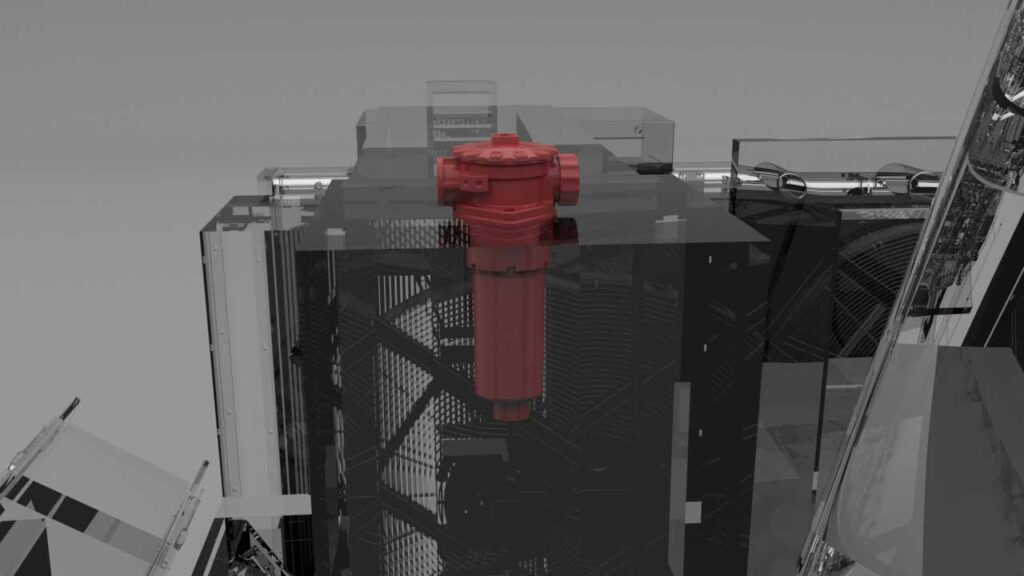

Hydraulic Filtration

-

Filter media optimized for mobile applications

-

Filter technology allows for tank optimization

-

Quality protection to ensure aftermarket sales (private labeling, custom designs, etc.)

-

High stable efficiency over complete filter lifetime

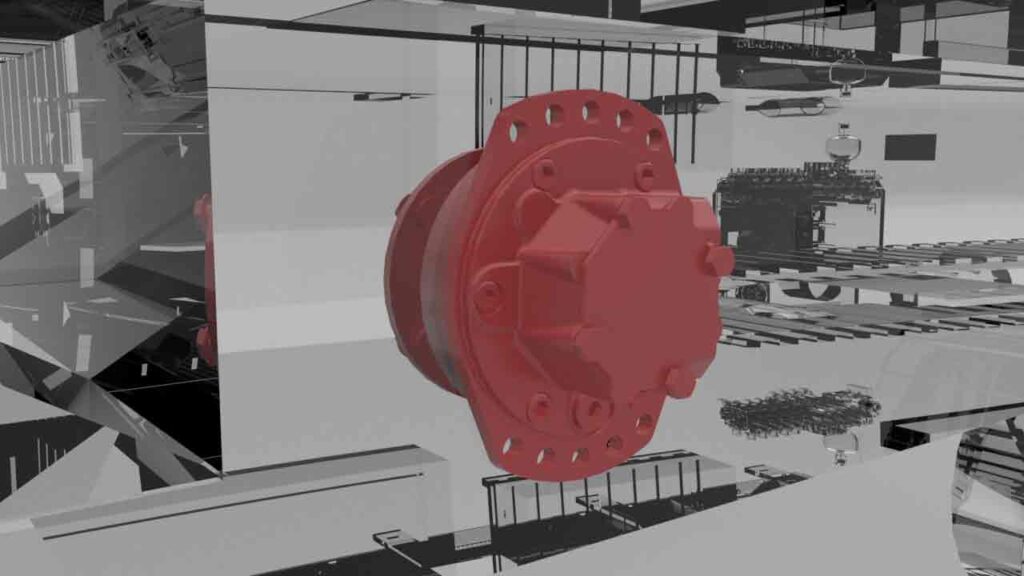

Radial Piston Motor

-

High starting efficiency (less heat, less horsepower loss and lower fuel consumption)

-

Higher temperature rating compared to other radial piston motors on the market

-

Factory sized for highest life expectancy

Bulk Scanner

-

Provides machine output to Controller/HMI/IoT solutions

-

Real-time feedback on the size of product in output

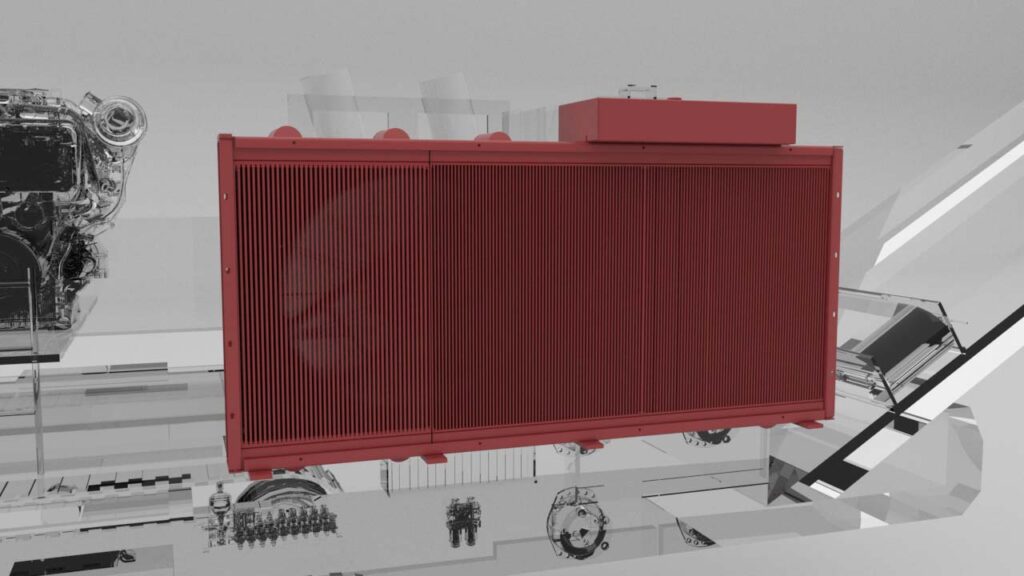

Combination Coolers

-

Customized cooler solution to optimize space claim on machine

-

Accurate sizing with computer simulation

-

Superior quality thanks to strict manufacturing guidelines

-

Manufacture domestically to reduce logistically lead times

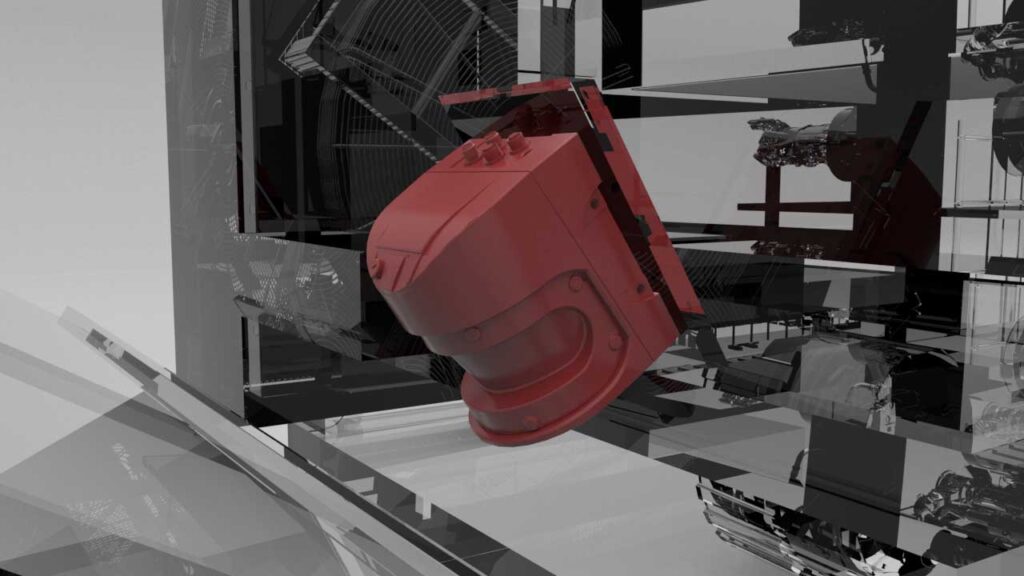

Safety Switches

-

Solenoid retained engagement to guarantee operator safety during operation

-

Coded sensor and receiver create a tamper-proof solution

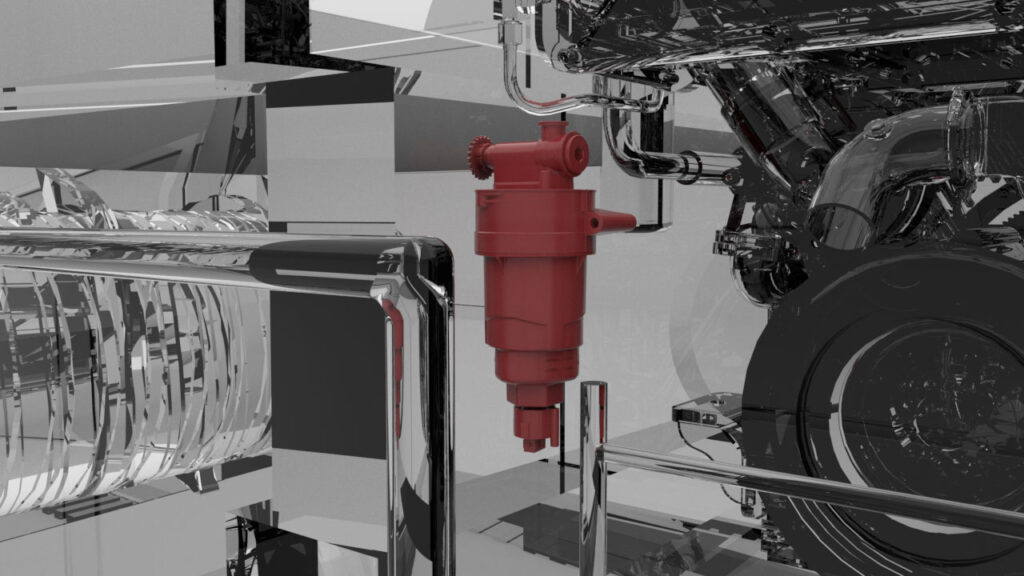

Fuel Filter

-

Separate layers for particle and water filtration

-

High dirt hold capacity

-

Higher water removal efficiency leads to longer fuel system life

-

Additional revenue stream for aftermarket parts

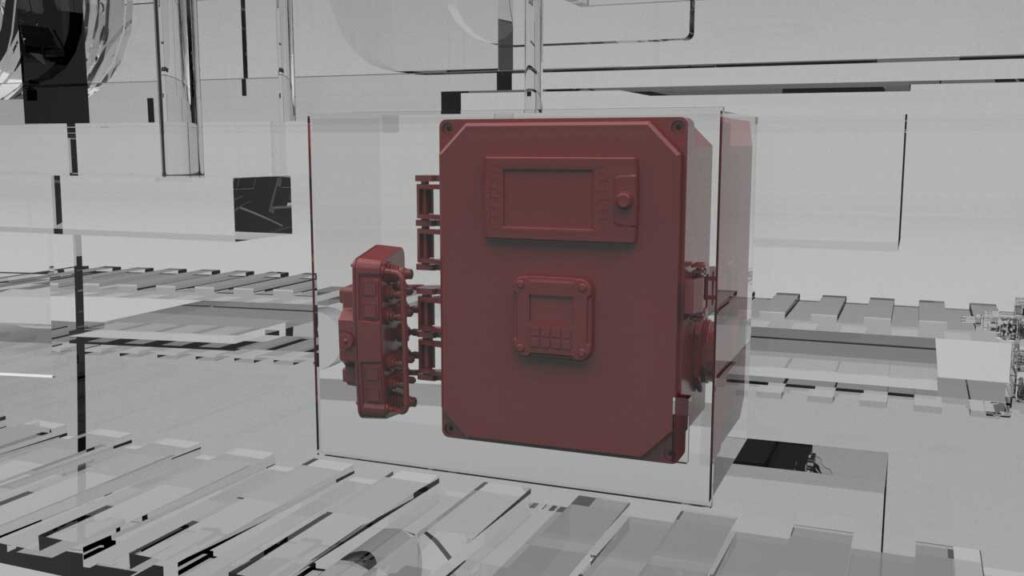

Control Panel/Radio Remotes

-

Customer-owned code for HMI/Machine Controller

-

One source for the complete electrical and hydraulic controls system

Auto Lubrication

-

Precise and accurate dispensing

-

Consistent replenishment

-

Decreases maintenance time

-

Reduces component wear