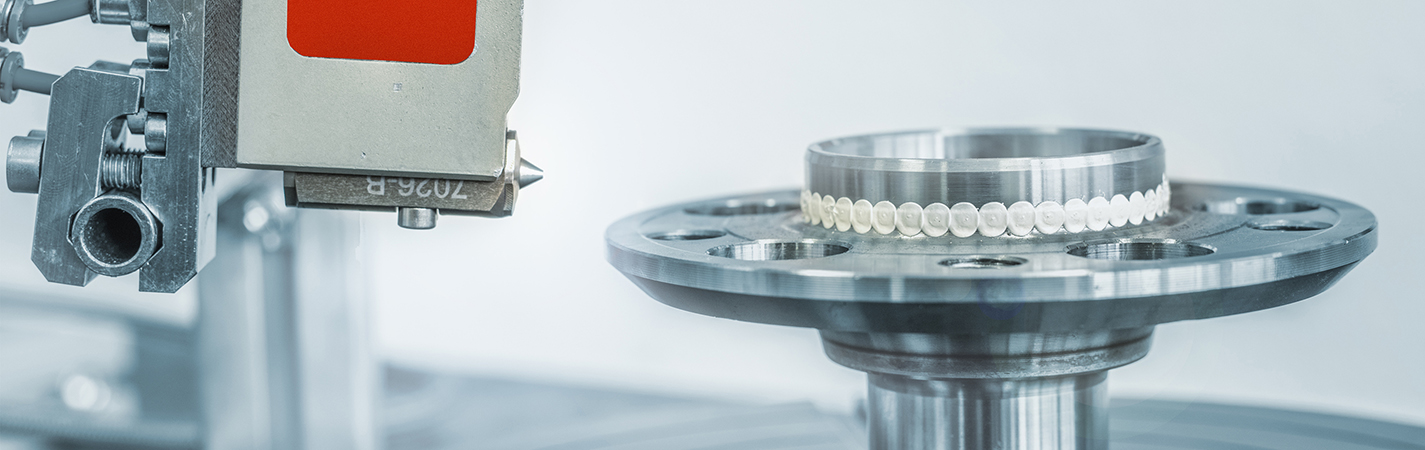

DOPAG's custom dispensing station for manual application of lubricants offers precise application with high repeatability. In their new case study, DOPAG shows how components such as O-rings and other seals can be greased or oiled with the help of an adapter. This process ensures that products are thoroughly sealed, and it is ideally suited for semi-automated assembly stations and fully automated assembly cells.

This metering method provides several benefits. In addition to providing precise application, this dispensing method also allows the user to avoid contact with the material. The adapter and entire system can be custom configured to fit your assembly process. Automotive assembly and fittings and valves for household appliances are a perfect fit for this application.

To learn more about the configurable dispensing solution, watch the video below:

Read the rest of the case study here.

DOPAG also has reliable volumetric metering valves suitable for low to high-viscosity media (greases, oils, adhesives, sealants, and silicones) that offer high repeatability. The pneumatically controlled metering valves dispense shot sizes of 0.001 ml to 100 ml. Dispensing valves are available in three different forms: needle, chamber, and handheld.

Needle – dispenses very small quantities up to 3ml per shot with high repeatability and short cycle times

Chamber – offer a larger range of shot sizes with a drip-free mechanism

Handheld – vertical handheld metering valves for manual use available in three sizes

DOPAG metering valves cover various applications requiring contact or contactless application. Application methods include dot, continuous, shot, and spray. With a dot application, the valves work on a volumetric principle, where the contents of the valve chamber are completely emptied upon a trigger signal. This allows for high repetition and flexibility by adjusting the volume. Dispensing, spray, and shot valves are discharged based on the valve needle's material pressure and opening time. This method allows for small quantities to be applied from a distance and continuous applications of any amount.

DOPAG offers several other metering and mixing technologies for greasing, bonding, sealing, potting, and gasketing. To learn more about DOPAG's technology and how Morrell Group can support your application, visit here.