The Morrell Automation Demo, or MAD Unit, was concepted, designed, engineered, built, and programmed in-house to showcase Morrell Group's full automation capabilities. The MAD Unit features five stations and a control panel simulating a flexible automation process. Each of the five stations has its own purpose and function. Empty containers and their caps travel through the conveyor system and stop at each station to demonstrate their function.

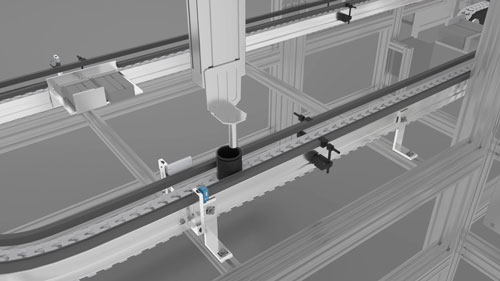

The containers' journey begins at the Part Introduction Station where a two-axis Cartesian system moves the container from a holding position to the Bosch Rexroth conveyor belt. The container travels down the conveyor system to a Smart Assembly Cell for a manual assembly step utilizing Rexroth's Nexo Handheld Nut Runner. The Nexo feels like a small controller in your hand, and it's programmed to provide the correct torque and angle for your fastening requirements. The preprogrammed nut runner ensures the assembly is accurate and properly recorded.

After the user places the container back on the conveyor belt, it travels to the Fill Station. This station demonstrates our advanced line synchronization capabilities, proving that we can support your system when it speeds up and slows down. Next, a high-speed pick-and-place system at the Dispense Station simulates processes used for machining, engraving, and other additive manufacturing steps. A basic pick-and-place unloads the container from the machining station and places it back on the conveyor belt. Then, the container and cap simulate pressing, bonding, or adhering two pieces together at the Joining Station. Finally, it returns to the Flexible Palletizer Station to be placed back in a holding position.

The MAD Unit demonstrates Morrell Group's diverse strengths as an Engineering Partner, Systems Integrator, and Value-Added Distributor and the benefits of working with our team. Integrating a broad range of products demonstrates our flexibility and product knowledge, allowing us to transfer these motion control examples to your application with ease. These stations required a lot of programming for proper communication to execute their tasks precisely and on time. Our team can assist with the programming and start-up of even the most complex solutions. At Morrell Group, we can be your partner from concept to completion. Visit the pages below to learn more about the technology used for each station on the Morrell Automation Demo. Or, get connected with our team today to discuss your application.