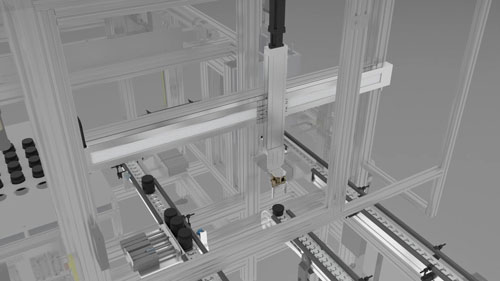

At the Part Introduction Station, the products are introduced to the MAD Unit via a two-axis Cartesian system from Bosch Rexroth. The cap is separated from the container and placed onto the inside conveyor belt, and both pieces continue to travel down their respective conveyor belts to the next station. This station includes a modular conveyor package, pneumatics, belt modules, an electric motor, electronic sensors, and safety components. The timing of this station has to be precise to maximize efficiency. Integrating a Siemens solution on the Part Introduction Station features our flexibility and product knowledge, another strength of Morrell Group and an Engineering Partner, Systems Integrator, and Value-Added Distributor (ESV).

How it Works

The container and cap are introduced to the MAD Unit via a two-axis Cartesian system from Bosch Rexroth. This Cartesian system is faster than the average robot. Bosch Rexroth's CKR15-110 belt module with an MS2N motor controls the x- and y-axes movements.

An AVENTICS G3 electronic Fieldbus valve system controls the pressure at the cap removal station. The pressure allows the gripper to grab the cap off the container and release it on the center conveyor. The G3 has a flexible, distributable architecture that modifies to meet a system's requirements, and it networks with all of the popular protocols: DeviceNet, Ethernet IP, Profibus, Profinet, and Powerlink.

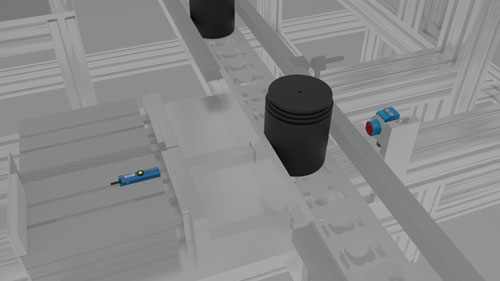

A SICK MPS Sensor is used to precisely position the container to prepare the gripper to remove the cap. The sensor continuously detects the position of a cylinder using a direct non-contact method. It contributes to the guided cylinder's movement, which moves into place to stop the container from moving further down the conveyor line. This intelligent T-slot position sensor can be easily integrated into a machine anytime, and no additional mechanical components or position elements are required.

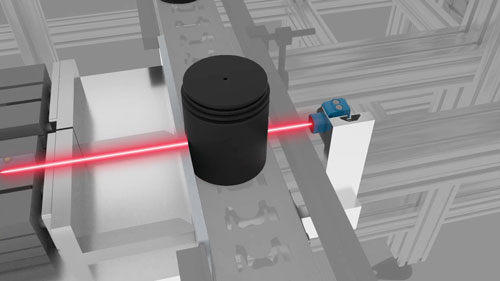

SICK H18 photoelectric sensors are used for part presence detection. Once the SureSense sensor detects the container, it triggers the motion of the gripper to remove the cap. The H18 is used to detect objects of various colors or materials. Its new and intuitive light strip indicates signal strength; the sensors have a range of 300 mm.

A Siemens SIMATIC S7-1500 PLC programmed in Siemens TIA Portal controls the Part Introduction Station. With single-cable technology, the SIMATIC S7-1500 PLC controls Bosch Rexroth servo drives and MS2N motors.

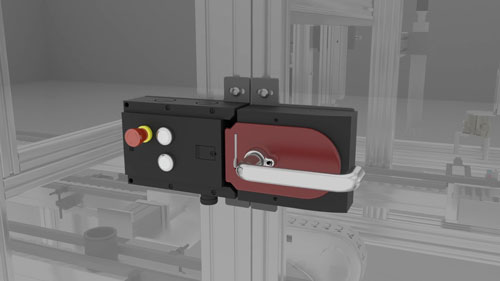

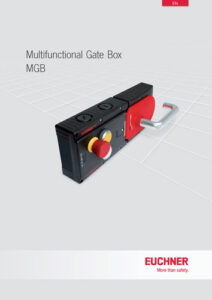

A EUCHNER Multi-Functional Gate Box (MGB) protects users from entering the enclosure while the machine is running. The MGB has two illuminated push buttons and an emergency stop button, according to ISO 13850. The modular design of the MGB is flexible if your application changes. The MGB is easy to mount and optimized for fences made of aluminum profiles or steel frames.

A SICK Locking Gate Switch triggers the machine to stop if the door is opened. This locking device has a rugged metal locking head and a high locking force of up to 3,900 N. The door and locking monitoring have a high level of safety thanks to the self-monitoring conductor outputs (OSSDs) with PL 2 (EN ISO 13849).