The Joining Station is designed as an offline loading and unloading station, featuring our flexible machining capabilities. This station features the daisy-chain functionality of Bosch Rexroth's servo technology, quality linear motion, and safety components. The Joining Station concept is transferrable to several different press operations, and Morrell Group applies this advanced technology to your application.

How it Works

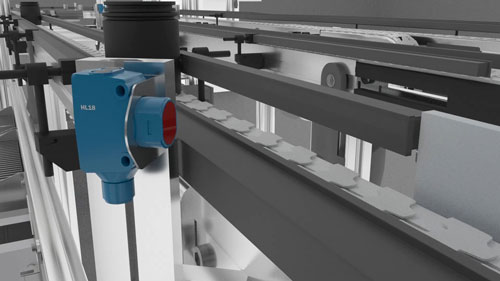

As the cap and container travel down the conveyor, the SICK H18 sensor detects the container and cap, triggering the gripper to move and grab the container. This photoelectric sensor in the SICK SureSense family provides reliable detection of the most complex objects, including black, shiny, transparent, and varying colors. The H18 sensor is built into VISTAL housing, which is nine times stronger than ABS housing, making it suitable for even the most rugged applications.

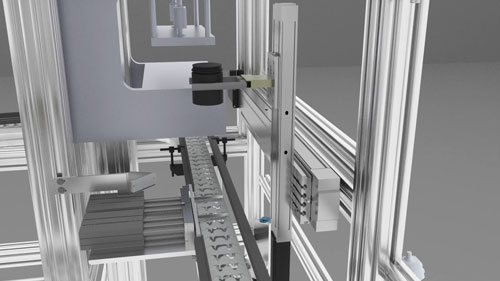

The gripper is controlled by air pressure through an AVENTICS HF03 valve manifold system with SERCOS III communication. One valve uses guided cylinders to stop the container from traveling down the conveyor. Another valve controls the gripper, which grabs the cup and places it on the press stand to be sealed. The HF03 pneumatic directional control valves have high flow capacity and a lightweight polymer design.

The gripper moves along the 7xz gantry system. Bosch Rexroth's CKK ball screw modules with an MS2N motor and KMS motor control the x- and z-axes. The compact CKK module provides high rigidity, high load capacities, and optimized travel performance. The MS2N synchronous servo motor has a high power density for compact machines. The KMS near-motor servo drive allows users to integrate a range of motors into an IndraDrive Mi drive chain. The KMS can be used where motors without integrated inverter electronics are required or where space is tight.

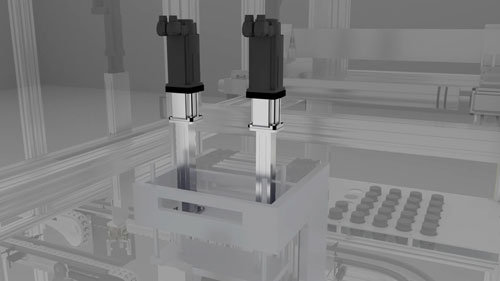

The Joining Station is controlled by two electro-mechanical cylinders, EMC40s, from Bosch Rexroth. Synchronized KSM servo motors and integrated servo drives drive the EMC40s. The EMC40 is designed to produce high thrust and speed capability with more flexibility and control for applications that historically used hydraulic or pneumatic cylinders. The EMC40 provides high performance with maximum cost-effectiveness.

IndraControl XM22, programmed in IndraWorks from Bosch Rexroth, controls the entire station. The XM22 has modular expansion options with extension and I/O modules. This component is ideal for both centralized and decentralized controlled topologies. The controls are based on the latest chip technology and scaled for performance and function.

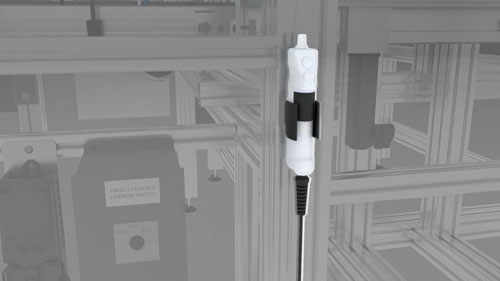

A EUCHNER ZSM live man switch is used for teaching the press and limiting the speed of the press. The ZSM switch has a modular design, allowing many additional functions to be integrated. The ergonomic design can be modified to include additional components, including a stop device, LED displays, or a key-operated rotary switch.

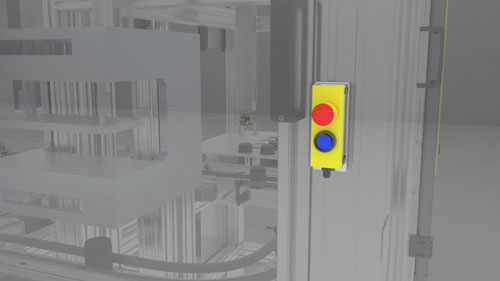

A SICK E-Stop button stops the entire machine when pressed. This instant halt of the machine protects the user and allows for any corrective action. The optional reset button restarts operations once the area is safe. The buttons are easy to mount thanks to their snap-in connection. Commissioning is quick with a simple M12 plug.

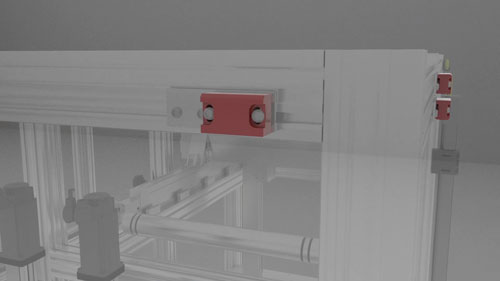

EUCHNER non-contact safety switches on the enclosure doors serve as a safety mechanism that does not require a key to open the enclosure safely. This safety switch series is ideal for systems with many safety doors to monitor since it's engineered to connect up to 20 safety switches in a series. It is easy to mount due to the actuator's and switch's small designs, and the switch has a high level of protection against tampering.