Plug & Produce with the New Smart Press Kit

With the new Smart Function Kit for Pressing and Joining, Bosch Rexroth delivers – for the very first time – a ready-to-use system of proven Rexroth components for joining processes, including an easy, web-based software solution.

The Smart Function Kit for Pressing and Joining consists of perfectly matching hardware and software components. It can be used either as a standalone solution or integrated in higher-level systems via fieldbus.

Call 248-373-1600 to schedule a live demo, or email us

One System Solution, Many Benefits

Easy Product Selection

- Preselected mechanical, electrical and software components from Bosch Rexroth are combined in various kits for forces from 2 to 30 kN

Plug & Produce

- Delivered in a single package, including preinstalled operating software

- Auto parameterization of the servo drive

- Small number of interfaces (servo drive with integrated motion control)

Zero Programming

- No programming knowledge required

- Easy and logical configuration of the process and the evaluation elements

- Browser-based web HMI can be used on various devices

- Modern and intuitive design

Smart Press Kit Infographic

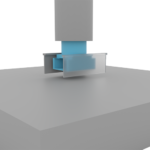

Cylinder – EMC

Parallel or In-Line motor attachment

Data access via ReST programming interface

IndraDrive HCS01

Mounting and Joining Applications

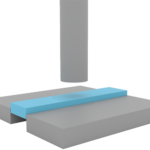

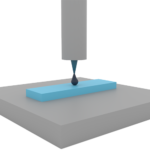

Press Fitting

Examples: Stator packages for electric motors

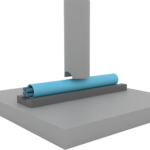

Crimping

Examples: Hoses, cables and plastic parts

Pressing

Examples: Sintering or powder press applications

Riveting

Example: Economical joining of sheet metal parts

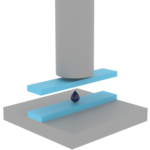

Bonding

Examples: Bonding of plastic and composite materials

Caulking

Examples: Integration of magnets in lamination stacks

Welding

Examples: Hot plate welding

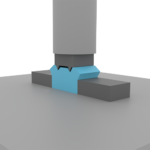

Clipping

Example: Connector contacts in connector housing

Forming Applications

Bending

Examples: Pipes in the metal industry

Embossing

Examples: Logos in plastic film

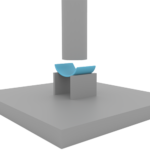

Deep Drawing

Examples: Production of packaging

Shaping

Example: Boxes in the packaging industry

Testing Applications

Measurement

Examples: Test stands

Testing

Examples: Test setups for dampers, springs, brake pedals

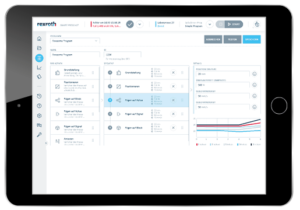

Intuitive Software

Commissioning with Auto Configuration (Plug & Produce)

- Preinstalled software

- Wizard for fast, easy commissioning

- Automatic loading of hardware configuration

- Auto parameterization of the servo drive

- Support for commissioning with homing and jog mode

Benefits

- Time savings thanks to Plug & Produce

- Fewer errors and increased productivity

- Significantly reduced complexity

Simple Programming and Operation

- Modular process configuration with drag and drop

- Logic check of input data

- Easy graphical creation o evaluation and analysis elements

- Visualization of process and status information in the dashboard

Benefits

- High level of user-friendliness – no programming knowledge required

- Error reduction and avoidance

Analysis and Diagnosis via Dashboard

- Analysis of force-displacement curves

- Visualization of the process result (OK/NOK)

- Storing of process data for quality assurance in an internal database

- Press history with filter and export function

- Diagnostic functions: system parameters as well as status reports and statistics

- Log book with plain text error messages integrated in the software

- Data access via ReST programming interface

Benefits

- Always up-to-date with current process data such as position, force and speed

- Short reaction times in case of deviation

Kit Specifications

| Size | SPK 002 | SPK 004 | SPK 007 | SPK 012 | SPK 019 | SPK 030 |

|---|---|---|---|---|---|---|

| Stroke [mm] | 35…400 | 40…400 | 65…400 | 80…400 | 70…400 | 90…400 |

| Nominal force [lbs] | 450 | 900 | 1580 | 2700 | 4270 | 6745 |

| Max. force [lbs] | 675 | 1350 | 2250 | 3370 | 4500 | 8990 |

| Max. velocity [m/s] | 0.38 | 0.32 | 0.55 | 0.5 | 0.37 | 0.5 |

| Force sensor/measurement | ||||||

| Measurement technology | Strain Gauge | |||||

| Measuring range [kN] | -0.3…+3 | -0.6…+6 | -1…+10 | -1…+15 | -1…+20 | -1…+40 |

| Sampling rate [Hz] | 1000 | |||||

| Resolution [bit] | 14 | |||||

| Accuracy (linearity) [% FS] | +/- 3 | |||||

| Servo drive (with integrated motion control) | ||||||

| Power supply [V] | 1 x AC 110…230 3 x AC 110….230 | 1 x AC 110…230 3 x AC 110….230 | 3 x AC 200…500 | 3 x AC 200…500 | 3 x AC 200…500 | 3 x AC 200…500 |

| Safety functions acc. to EN 61800-5-2 | Safe Torque Off (STO) 1) | |||||

| Fieldbus interface | Profinet, Ethernet/IP, EtherCAT, Sercos III | |||||

| Software functions | ||||||

| Max. number of programs | 99 | |||||

| Number of program steps per program | 500 | |||||

| Number of digital inputs/outputs | 6 inputs + 1 output or 7 inputs | |||||

| Force measurements | Unlimited without resolution reduction | |||||

| Evaluation elements | Windows, envelopes, thresholds | |||||

| Ambient conditions | ||||||

| Ambient temperature (operation) [°C] | 0–50 °C (loss of performance at temperatures exceeding 40°C) | |||||

| IP protection class | Mechanics: Standard IP54 (up to IP65 possible) Control cabinet hardware: IP20 |

|||||

| 1) Category 4, Performance Level e according to EN ISO 13849-1 and SIL 3 according to EN 62061 | ||||||

Smart Function Kit for Handling

The Smart Function Kit for Handling was designed to move components or workpieces in defined spaces with precision and dependability, this mechatronic solution relies on a Cartesian single- or multi-axis system.