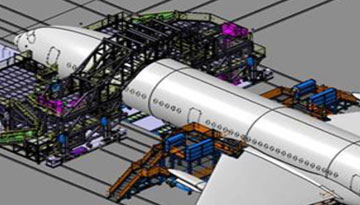

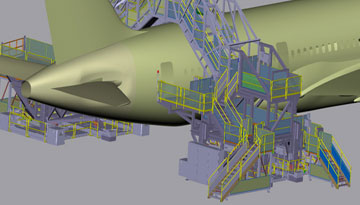

Stegner Aerospace is a motion control company focused on the automation of tools used in the manufacture and assembly of commercial and military aircraft, rockets, and satellites.

The company stands out in three key ways:

Stegner Aerospace is renown for its technical ability, offering a deep understanding of both motion and controls – everything needed, at the highest level, for automated tooling solutions. All from one source.

More than a build-to-print resource, Stegner Aerospace offers a complete portfolio of services that simplifies meeting the changing demand for flexible and automated tooling.

Stegner Aerospace can provide concept engineering, process engineering, integration, and service and maintenance – any of these requirements, or all of them as a turnkey deliverable, depending on customer need.

Stegner Aerospace is unique in the aerospace industry for its concept engineering process and the innovation and savings this process provides.

It begins by working through layers of alternative system concepts, moving step-by-step through initial simple sketches to increasing detailed drawings, considering all motion control technologies, risk and safety issues, applicable standards, and systems and approaches proven in other industries.

Only then does it recommend a motion control solution. No other company provides such a thorough, up-front analysis to truly understand customer need.

Concept Engineering

- Process development

- Controls architecture

- Prototype systems

- Research and development

Process Engineering

- Electrical design

- Software Design

- Risk assessment

- Component sizing and selection

Integration

- Program management

- Field installation

- System validation

- Quality assurance

Services & Maintenance

- Training

- Installation/start-up

- Production support

- 24/7 service hotline