Metering and Mixing Dispensing Technology from DOPAG:

- Greasing, bonding, sealing, gasketing, & potting

- Shot, spray, continuous, & dot

- 40+ years of industry expertise

- Concept engineering

- R&D for each application

- Custom automation solutions

- Technical center for testing

- In-house fluid compatibility tests

- Material manufacturers collaboration

- Over 2,000 materials tested

- Monitoring and integrated solutions

- Validation of dispensed material

Precision Metering and Mixing Dispensing

DOPAG is one of the leading metering and mixing systems manufacturers for multi-component media like polymers and epoxy resins and single-component media such as silicone, greases, oils, and adhesives. The high-quality standards of DOPAG products guarantee maximum precision and repeatability of results – even in highly automated processes. DOPAG fluid dispensing systems offer a variety of application techniques: shot, spray, continuous, or dot.

DOPAG's 1K metering systems precisely deliver adhesives, sealants, greases, and oils from their original containers to the application spot. The material is then applied to the workpiece shotwise or in a continuous bead shape. One-component media can be delivered via a material pressure vessel - in case of a flowable or low-viscosity medium - or a drum pump installed on a double pump station for middle to high-viscosity media. The application can be carried out manually or automatically.

Weight reduction and the versatility of new adhesives have made bonding popular in industries that join disparate materials and improve sealing techniques. DOPAG has been able to assume a leading position in the market because of its constant optimization of its fluid dispensing systems. They apply adhesives precisely and in the correct amount. This precision and accuracy prevent the waste of adhesive and sealants, providing optimal visual results.

DOPAG's 2K metering and mixing systems can process multi-component media such as epoxy resins, polyurethanes, and silicones. Different basic configurations featuring a modular design are available and can be explicitly configured to your demands. Homogenous mixing of the components becomes extremely important when processing multi-component materials. Wide differences in media viscosity, short pot life, and components that are difficult to mix require different mixing systems.

DOPAG offers dynamic mixing systems, static mixing systems, a static-dynamic mixing system, and mixer element monitoring for static-dynamic mixing systems. DOPAG is the system provider for gasketing, bonding, sealing, potting, and automating. The dynamicLine is based on the newly developed dynamic mixing head with its innovative valve technology. With this technology, DOPAG has raised the bar and set a new benchmark regarding ease of use, accuracy, and reliability for dynamic mixing. The high-performance mixing head is based on 40 years of experience with two-component, low-pressure metering and impresses with its unique valve technology with a booster. The variability of DOPAG's potting systems means they achieve all requirements for precise mixing, metering, and application of resins, always aligned to the individual needs of customers.

DOPAG's fluid dispensing systems will deliver on all your mixing and metering needs no matter your market: automotive, aerospace, transportation, glazing, wind power, white goods, LED, construction, or electronics. Moreover, they will save on time, effort, and materials while increasing your ROI.

1K Metering Systems

DOPAG 1K metering systems handle precision industrial applications of adhesives, sealants, lubricants, and silicone with ease.

Coredis

Modis

Vectodis

The 1K metering systems lubricate these automotive parts:

- Engine, gearbox, interior, body, exterior, chassis, & powertrain

- Drum pumps, pressure vessels, & transfer pumps

- Pressure regulators

- Dispensing & metering valves

- Control units

The 1K metering systems bond and seal these areas:

- Engine, gearbox, & clutch

- Dosing system with drum pump

- Gear pump system

- Gear & piston metering system

2K Metering Systems

DOPAG’s 2K system, which processes multi-component media, utilizes three of the most popular systems: Eldomix, Vectomix, and Variomix.

Eldomix

The Eldomix 100/600 models of metering and mixing systems are compact, solvent free, and gear-pump driven. They are used to apply low to medium viscosity, multiple-component materials such as epoxies, polyurethanes, and silicones.

Vectomix

Variomix

In the automotive industry, these systems are used for:

- Encapsulating electronics & stators

- Sealing electronic & cable housing

- Bonding lightweight components, sheet metal, & battery housings

- Processing thermally conductive materials & stator encapsulation

These systems produce Automatic Dynamic Mixing for:

- Gasketing, potting, & bonding for the battery of e-mobility, door panels, & loudspeakers

- Dynamic mixing heads

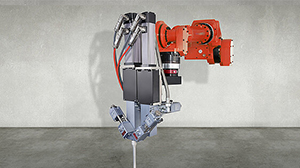

- Linear & industry robots

Automated Dispense Applications for Aerospace

Volumix is suitable for automated applications of light polysulphides in the aerospace industry and can seal all aircraft components. The applications for sealants are many and varied:

- To fill gaps in the assembly process

- To protect against corrosion, e.g., sealing rivets

- To seal fuel tanks & wings

- As aerodynamic seals, e.g., on the outer skin & window frames

- To seal edges (to avoid the annealing effect in fuel tanks)