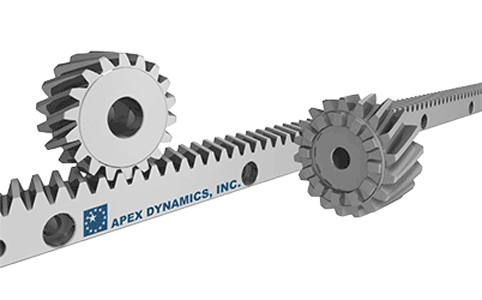

APEX high speed, low noise, and long life precision rack and pinion have extended travel capacities without adding inertia and high force capacities for high performance and long service life. High loading rates allow up to 204 kN. Like ball screw systems and linear motors, APEX precision rack and pinion are perfect for applications requiring a high force, travel capacities, and extreme precision. Precision rack and pinion use preload designs to engineer highly accurate systems for machine tools and measurement systems.

- Defined straightness, parallelism, and perpendicularity

- Helical angle and pressure angle with tolerance

- Geometrical tolerance of all dimensions

- Defined surface roughness of teeth

- Defined hardness and thickness of the hardened layer on teeth

Precision Rack and Pinion Facts & Features

APEX provides nine qualities of racks and eight variations of pinions with right- or left-handed helical teeth and ten qualities of racks and two qualities of pinions with straight teeth. Material options are carbon, alloy steel, or Q&T alloy steel.

Rack: -13 - 0 / -15 - 0 / -22 - 0 / -48 - 0 / -63 - 0 / -90 - 0 (μm)

Pinion: e24 / e25

Helical: Q10 / Q8 / Q8H / Q6M / Q5 / Q5H / Q4

Straight: Q10 / Q9 (Stainless) / Q8 / Q8H / Q6M / Q5 / Q5H / Q4

Helical: 1 / 1.5 / 2 / 2.5 / 3 / 4 / 5 / 6 / 8 / 10 / 12

Straight: 1 / 1.5 / 2 / 2.5 / 3 / 4 / 5 / 6 / 8 / 10 / 12 / Pitch 5 / Pitch 10 / Pitch 13.33

- Applications requiring high rigidity & high torque

- Automatic loading systems

- Certification laboratory

- Clean room applications

- Combination with linear guide

- Food industry

- High-end machine tools with electrical preload

- Lifting axes

- Linear axes with low load feed

- Machine tools

- Multi-pinion applications

- Outdoor applications

- Pharmaceutical industry

- Portal machine center

- Robots

- Stainless

- Tube bending machines

- Water & laser-cutting machines

- Welding machines

- Woodworking machines

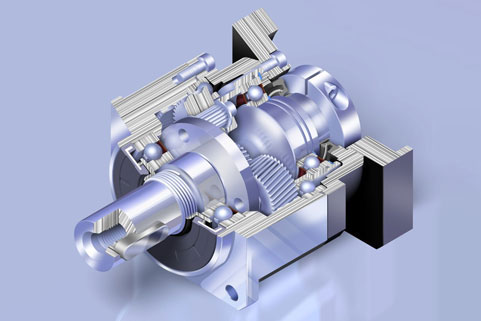

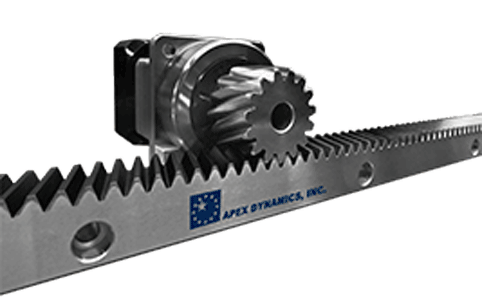

APEX Precision Rack and Pinion Gearboxes

The KH-Series high precision right angle gearbox has a 90° input via a hypoid gear set. It's suited for APEX precision rack and pinion and has short, light, rigid housing and full compatibility with standard motor adapters. It features low noise, easy mounting, and a compact structure. The KH-Series is available as spline, keyed, and shrink disc.

- Output torque T2N: 18 Nm - 1,600 Nm

- Ratios - 1 stage: 3 / 4 / 5 / 7 / 10

- Low backlash - 1 stage: ≤ 3 arcmin

- High efficiency - 1 stage: ≥ 96%

- KH060 / KH075 / KH100 / KH140 / KH180 / KH210 / KH240

Resources

Find Your Best Fit Precision Rack and Pinion.