Automakers are quickly moving to the electrical vehicle (EV) market. An increase of EVs in production results in a greater need for battery cycling DC testing. EVs also require metering and mixing systems for processes such as thermal conductive, electronic potting, and lightweight composites. Morrell Group is well-equipped to support this rapid increase in testing needed with our Battery Cycling DC Testing Solutions. Many dispensing solutions are available for EV manufacturing processes with DOPAG metering and mixing technology for multi-component media through Morrell Group, a trusted ESV.

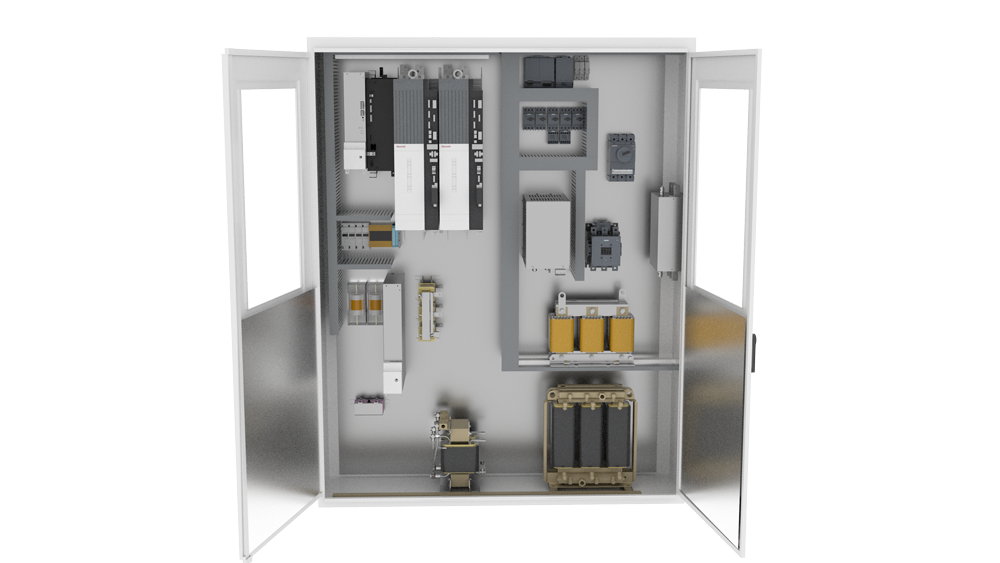

Battery Cycling DC Testing Solution

Morrell Group's Battery Cycling DC Testing Solution provides clean DC voltage and highly dynamic current with a future-proof design for your evolving end-of-line testing needs. The modular Rexroth platform with open core engineering enables quick adaptation to changing application requirements. It can supply multiple battery cyclers, simulators, and motor inverters.

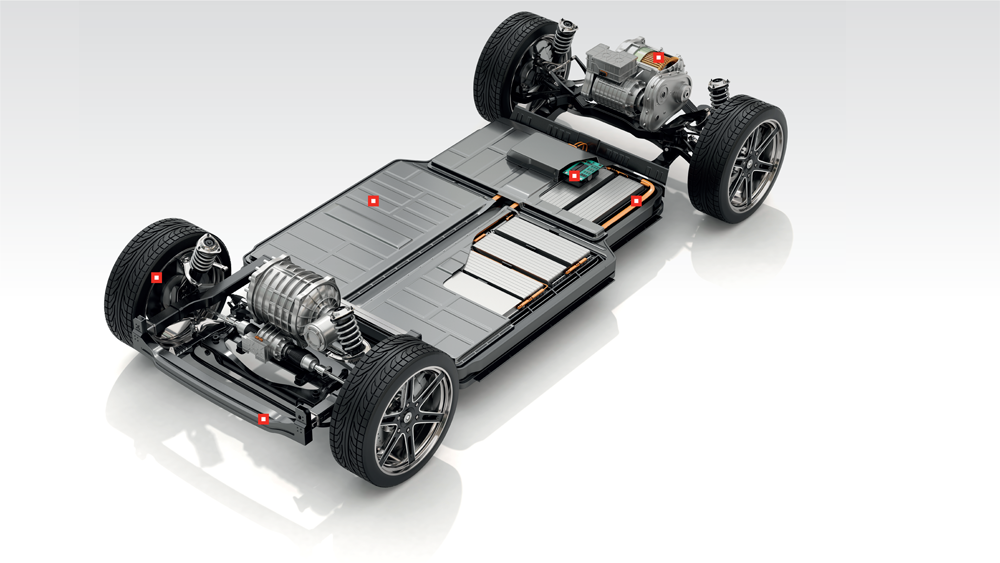

Dispense Solutions for Electric Vehicles

DOPAG metering and mixing systems are for multi-component media like polymers and epoxy resins as well as single-component media such as silicone, greases, oils, or adhesives. They are used in electric vehicle manufacturing processes such as bonding, sealing, gasketing, greasing, oiling, thermal conductive, electronic potting, and lightweight composites.